How to Pour Concrete Footers for Jack Posts

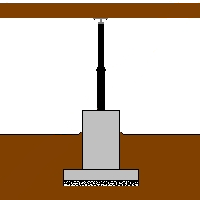

This tutorial explains how to pour concrete footers for jack posts used in house raising or leveling sagging floors, porches, sun decks and room additions. Traditionally built short and stout, they can also take a vertical form with a proper base. Usually steel reinforced and poured with high-strength concrete, these footers should long outlast the supported structure.

|

Things You'll Need:

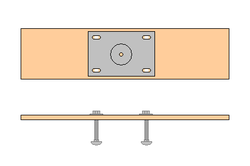

* 1/2" & 3/8" Rebar Steel Rods * Flat & Pointed Shovels * Finish Trowel * Wheelbarrow * 5000 PSI Concrete (high strength) * Gravel * 12" x 48" Concrete Form Tube * Tape Measure * Straight Line * Utility Knife * 6" x 16" plywood board * Drill w/ 3/8" Bit * 2' Level * 4-3/8" x 3" Carriage Head Bolts, Flat & Lock Washers, Nuts * 4-3/8" x 1-1/4" Lag Bolts * Jack Post * Concrete Sealer * Paint Brush |

#ad #ad |

#ad #ad |

|

Tips

* Contact https://www.missutility.net/ and have them locate underground services before you dig!

* Extend your adjustable jack post until it fits snugly between the footer and the floor trusses, then lengthen it by an extra ½ turn only. Allow 24 hours for the structure to "settle," before raising it another ½ turn.

* If using more than one jack post, adjust to achieve level before adjusting to raise the structure. Then adjust each jack evenly.

* These Footers can and should also be used with solid, non-adjustable, posts in new construction. Prevent sagging from the start!

Warnings

* Raising a sagging floor in a house? Basement slab floors are typically 4" thick at best and will crack if not reinforced!

* When raising a sagging structure, it is important to go slowly otherwise internal pressures will tear it apart.

* Sealing damp concrete will trap moisture inside which will expand when frozen and cause cracks.

* Be sure to present your plans and obtain all applicable building permits before construction.

Copyright 02/08/2009 All Rights Reserved. Questions? Comments? Contact Me

Related Articles:

Concrete

* Contact https://www.missutility.net/ and have them locate underground services before you dig!

* Extend your adjustable jack post until it fits snugly between the footer and the floor trusses, then lengthen it by an extra ½ turn only. Allow 24 hours for the structure to "settle," before raising it another ½ turn.

* If using more than one jack post, adjust to achieve level before adjusting to raise the structure. Then adjust each jack evenly.

* These Footers can and should also be used with solid, non-adjustable, posts in new construction. Prevent sagging from the start!

Warnings

* Raising a sagging floor in a house? Basement slab floors are typically 4" thick at best and will crack if not reinforced!

* When raising a sagging structure, it is important to go slowly otherwise internal pressures will tear it apart.

* Sealing damp concrete will trap moisture inside which will expand when frozen and cause cracks.

* Be sure to present your plans and obtain all applicable building permits before construction.

Copyright 02/08/2009 All Rights Reserved. Questions? Comments? Contact Me

Related Articles:

Concrete